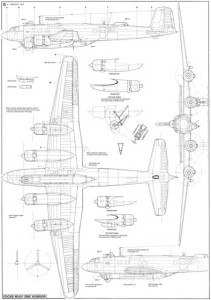

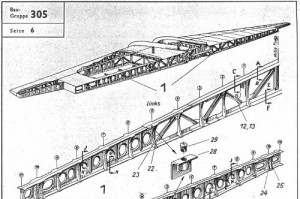

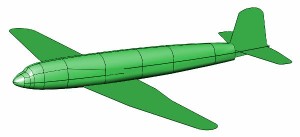

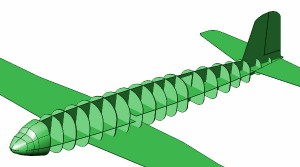

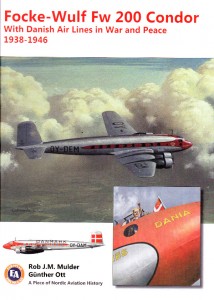

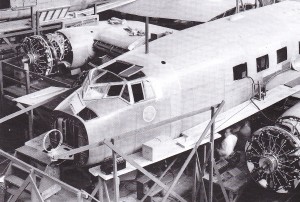

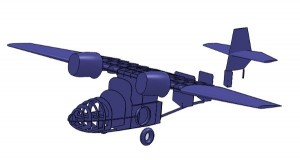

The Focke-Wulf Fw-200 was developed before WWII as a long-range passenger airliner. It was built to the specifications of Deutsche Lufthansa, and was developed by Kurt Tank. It first flew in 1937. It was an all-metal, four-engined monoplane capable of carrying 25 passengers up to 3,000 km. The Fw-200 was purchaced by Det Danske Luftfartsselskab (Danish Airlines) and was used for passenger transport by DDL well into the war.

The Focke-Wulf Fw-200 was developed before WWII as a long-range passenger airliner. It was built to the specifications of Deutsche Lufthansa, and was developed by Kurt Tank. It first flew in 1937. It was an all-metal, four-engined monoplane capable of carrying 25 passengers up to 3,000 km. The Fw-200 was purchaced by Det Danske Luftfartsselskab (Danish Airlines) and was used for passenger transport by DDL well into the war.

The Fw-200 was the first aircraft to perform a non-stop flight across the Atlantic, from Berlin to New York, causing quite a stir in the USA, and a lot of pride in Germany. The trip took place on the 10th of August 1938, and took approximately 24 hours. The return trip took less than 19 hours.

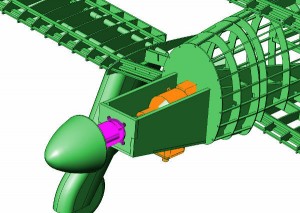

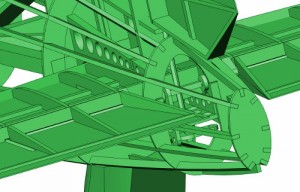

The German Fw-200’s were modified for war-time use, and was particularly successful over the atlantic for maritime partols and anti-submarine work. The war-time modifications were installation of gondolas and machine-guns, as well as radar.

Hitler had a Fw-200 converted from airliner status to personal aircraft. It was marked D-2600 and named Immelman III, in honour of WWI flying ace Max Immelmann.

After the war, a large number of surplus Boeing DC-3’s at knock-down prices, meant that the otherwise superior Focke-Wulf Fw-200 didn’t stand a chance. However, the Focke-Wulf Fw-200 was so far ahead of its time that, had it not been for the war, Focke-Wulf might have been one of the most popular airliner manufacturer today.

A single Fw-200 was raised from a lake in Norway in the 1990’s and is being restored in Berlin.

Specifications:

Crew: 5

Capacity: 17-25 passengers or 30 fully-armed troops

Length: 23.45 m (76 ft 11 in)

Wingspan: 32.85 m (107 ft 9 in)

Height: 6.30 m (20 ft 8 in)

Empty weight: 17,005 kg (37,490 lb)

Max takeoff weight: 24,520 kg (50,057 lb)

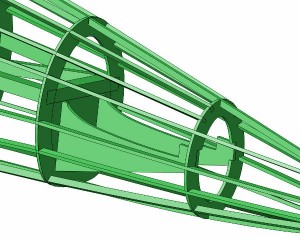

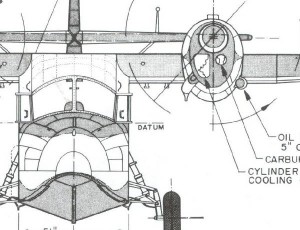

Powerplant: 4 × BMW/Bramo 323R-2 nine-cylinder radial engine, 895 kW (1,200hp) each

Maximum speed: 360 km/h (195 knots, 224 mph) at 4,800 m (15,750 ft)

Cruise speed: 335 km/h (181 knots, 208 mph) at 4,000 m (13,100 ft)

Range: 3,560 km (1,923 nmi, 2,212 mi)

Endurance: 14 hrs

Service ceiling: 6,000 m (19,700 ft)

Armament: 1 × 20 mm MG 151/20 cannon, 4 × 13 mm MG 131 machine guns

Bombs: Up to 2,100 kg (4,360 lb)

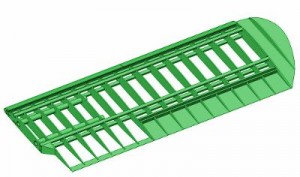

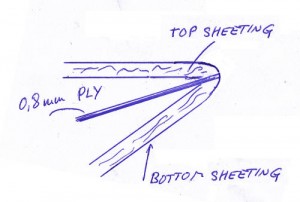

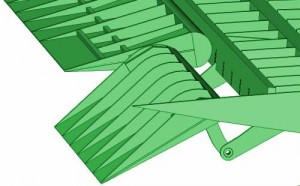

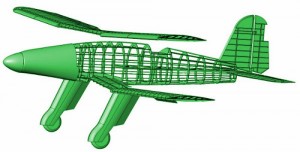

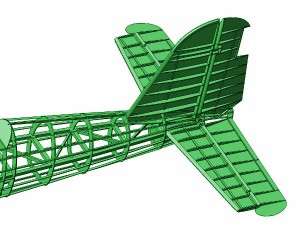

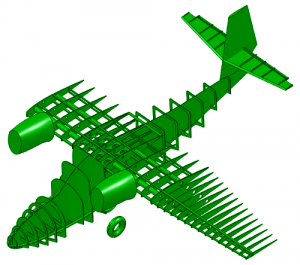

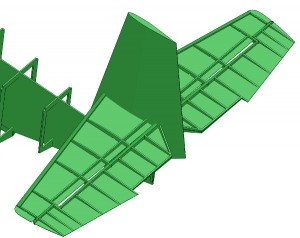

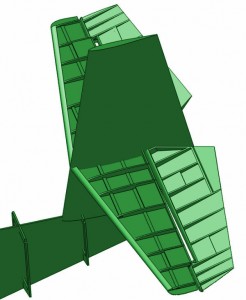

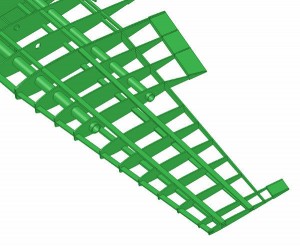

The Fieseler Fi-167 aircraft had a ridiculous amount of high-lift devices. It is said that Gerhard Fieseler during a demo sank the aircraft from 9800 ft to 100 ft, practically over the same spot while having full control over the plane. Ths is probably the aircraft with the most slats and flaps ever built. The Fi-167 had 2 automatic and independent slats on each wing – very exciting, but it will be hell to model. Not only were there a lot of high-lift devices, but they were also huge. A total of 10 percent of the chord is slats and 20 is flaps approximately.

The Fieseler Fi-167 aircraft had a ridiculous amount of high-lift devices. It is said that Gerhard Fieseler during a demo sank the aircraft from 9800 ft to 100 ft, practically over the same spot while having full control over the plane. Ths is probably the aircraft with the most slats and flaps ever built. The Fi-167 had 2 automatic and independent slats on each wing – very exciting, but it will be hell to model. Not only were there a lot of high-lift devices, but they were also huge. A total of 10 percent of the chord is slats and 20 is flaps approximately.

27/08/2011

27/08/2011