The most common material for making R/C scale models is without doubt wood. Many different types of wood are used, and the most common are balsa, spruce and plywood. All of these wood types are available from your local hobby shop.

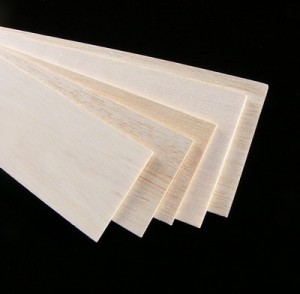

Balsa Wood

Balsa wood is extremely light-weight and is available in soft, medium and hard varieties. Hard balsa may be used for longerons, but not for sheeting. Soft balsa is ideal for thicker carved pieces, like wing tips and pilots, while medium balsa is ideal for sheeting and some smaller longerons. Balsa is best cut using a scalpel. Thicker pieces may be cut using a hacksaw.

Balsa wood is extremely light-weight and is available in soft, medium and hard varieties. Hard balsa may be used for longerons, but not for sheeting. Soft balsa is ideal for thicker carved pieces, like wing tips and pilots, while medium balsa is ideal for sheeting and some smaller longerons. Balsa is best cut using a scalpel. Thicker pieces may be cut using a hacksaw.

Balsa is bendable by soaking it in Windex or any other liquid containing ammonia.

Because of its light weight and lack of strength, balsa spars are rarely used on aircraft above 1.5m in wingspan. Balsa sheets with a thickness of around 1.5 or 2 mm, however, are used for sheeting the fuselage and wings on most aircraft from 1.8m and up.

Hardwood

Hardwood is quite heavy and is used sparingly. While balsa actually belongs to the family of hardwood trees, it is in fact very soft, and other wood sorts are used where higher strength is required.

Spruce is most often used as wing-spars, and beech is used for engine mounts. When selecting spruce, make sure the wood has very long fibres running parallel to the spruce.

In North-America where global warming has made it possible for a spruce-eating beetle to thrive, a new wood-sort called Cyparit is used. I have not used this material, and can not comment on it, but apparently it works quite well as a substitute for spruce.

Plywood

Plywood is used where balsa-sheets are too weak structurally. Engine boxes are typically made from thick plywood. wing ribs, landing-gear mounts, and fuselage formers are also made of plywood.

Plywood is available in aircraft-grade, standard and light-ply. Aircraft grade is expensive and not often used. However, it often consists of 5 ply, and is a lot stronger than the normal (3 ply grade). Light-ply is used a lot in the USA, primarilly for fuselage formers, but it is not very stong.

When building an aircraft, pay attention to the strength/weight issue and use only the really heavy, but strong, plywood where it is required.

Plywood is available in thicknesses from 0.4 to over 6 mm. I generally only use plywood up to 3 mm, with the exception of engine mounting boxes. These thicknesses are for aircraft with a wingspan of around 2.5 m. 2 mm plywood is normally sufficient for smaller aircraft with a wingspan of around 1.8m.

Plastics

Many types of plastics are used today on r/c scale aircraft. Some, like PETG sheets are transparent and used for canopies and windows. Others, like nylon, are very strong and self-lubricating, and used for rudder horns, and hinges. Mylar may be bent over and over again and is typically used for smaller hinges.

Composit Materials

Two types of composit materials are commonly used. Carbon fibre and glass-fibre. Both are available in rowing (strands) and in woven mats. Glass-fibre is cheaper and is used together with an epoxy to cover aircraft fuselages and wings, to give the aircraft a hard shell. Carbon fibre rowing may be glued between sheets of balsa, with epoxy, to strengthen these plates. Carbon fibre tubes are available at some hobby shops, and they are extremely strong. Note that carbon fibre dust is seriously bad for your health.

PCB material (G10)

PCB material is basically glass-fibre plates. They are used in the electronics industry in great numbers. They are hard and strong and do not easily break. PCB material is available from 0.4 to 1.6 mm thickness. These plates are used for reinforcement and for cutting rudder-horns. This material is quite heavy.

Piano Wire

Piano wire is the work-horse of landing-gears, push-pull rods, etc. This iron wire comes in many diameters, and is slightly springy.

Piano wire is the work-horse of landing-gears, push-pull rods, etc. This iron wire comes in many diameters, and is slightly springy.

Lithoplate

Lithoplatea are very thin aluminium plates (0.3-0.4mm). These plate are used for decoration. They are soft when annealed (heated using a blow-torch).

Styrene

Styrene is a plastic, available in sheets, rods, and all kinds of shapes. It is easily cut, heated and pulled, drilled, or otherwise machined, using ordinary house-hold tools like scissors and pen-knives. This plastic is ideal for making cockpit interiours. A special filler is available from the hobby shop for styrene.

Plastic covering

Several types of covering films are available under various names like Monocote, Oracover, Ultracote, etc. They have a adhesive back, are fuel-proof, comes in a variety of colours, and are heat-shrinkable. These plastic films are ironed on using a tiny iron, specifically made for this purpose. Film covering in available at most hobby stores. These films are not used much for scale building, due to their shiny looks, though. For modelling metal aircraft, fibreglass and paint is most often used. For emulating WWI fabric covered aircraft, a film called Solartex, is available that has the same surface texture as linnen.

Very interesting stuff. Do you do any guest posting on other blogs?

No, I have not done that.

Admin