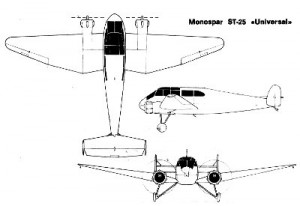

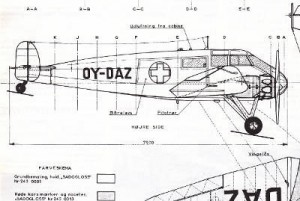

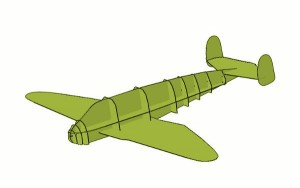

Without finishing my other two R/C Scale Plans, I have begun collecting information about my next plane. The Monospar S.T. 25. There is only one left – In Denmark of all places.

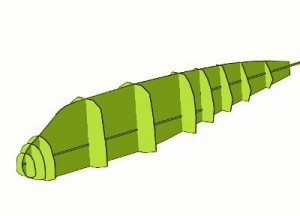

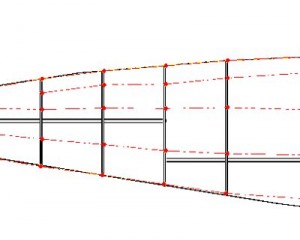

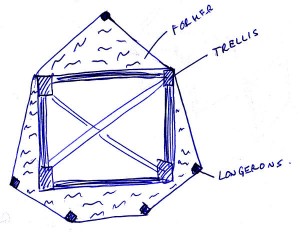

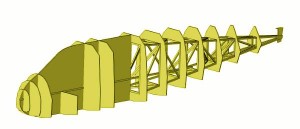

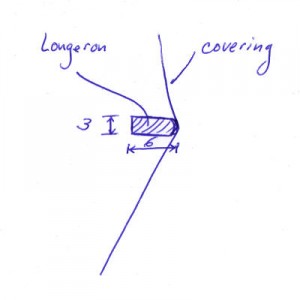

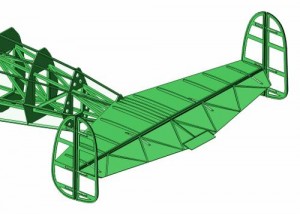

As the name implies, the wing in this plane has only one spar, and an ingenious way to keep it rigid, using bracing wires “spiralling” around the spar.

The S.T. 25 is the last in a series of almost identical planes, starting from the S.T. 4, then S.T. 10, 11, 12 and finally S.T. 25.

I was promised a decent 3-view of this plane by a guy in Denmark, but even without it, it is possible to piece a 3-view together, based on photos and 3-views of the other monospar models. They are that similar.

02/01/2010

02/01/2010

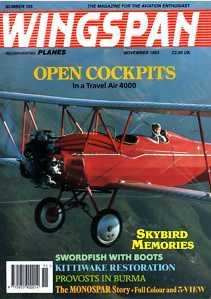

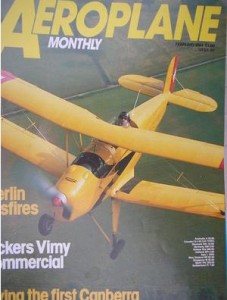

I have found a magazine on e-bay showing 3-views and the history of the monospar. It should be in the mail soon.

I have found a magazine on e-bay showing 3-views and the history of the monospar. It should be in the mail soon.

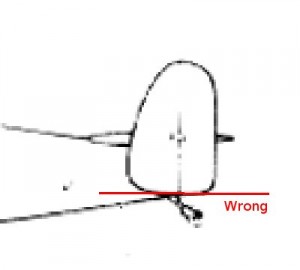

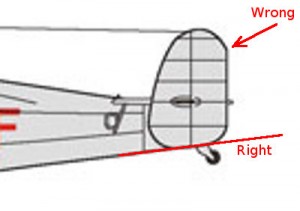

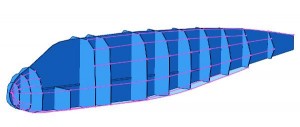

The S.T.25 is well suited to electric…good because of its extremely small

radial cowls. I have a plastic model made by Azur with decent detail and a

fair amount of docs gathered online from a New Zealand museum, and ambulance

version at your museum.

Ed Clayman

ScaleAero@gmail.com

http://www.FliteMetal.com