This build-thread is a bit different to the other threads here, in that I am building a CNC router, and not an airplane model.

This build-thread is a bit different to the other threads here, in that I am building a CNC router, and not an airplane model.

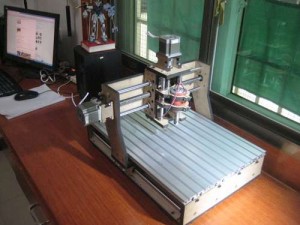

A CNC router is a computer controlled router that is able to cut out fuselage formers, wing ribs and other model parts from foam, balsa, plywood and even aluminium, directly from a PC. It will save me a ton of time, and ensure that all the parts come out identical.

The picture on the right shows a similar design to what I have in mind, only smaller.

Early on, I settled on a maximum parts size of 120 x 70 x 30 cm. In hindsight this is probably a little on the small side. Since I later had the idea of cutting entire cowl-plugs from foam with the CNC, I should have gone for 60 cm in the Z axis (upwards). Anyway, all is not lost, as I can “slice” the cowls in the software, cut out the slices individually, and then glue the slices back together again after they have been cut out. Not ideal, but it will work.

The largest size parts the CNC router can cut was not the only choice I had to make. Before starting the design, speed, accuracy, motor type, control electronics, cost and availability were all things that needed considering. I’ll quickly run through the various options.

- Speed is an obvious factor in a production environment, but for my hobby use, any speed will be faster than cutting parts out by hand, so I gave it a low priority.

- Accuracy is important, however, because of the small size parts I plan to make. I decided on an accuracy around 0.1 mm as “good enough”. Accuracy is determined by the motor type, and most importantly the drive-train. To avoid slop and backlash, I decided on a design with ballscrews and linear guideways. They are a quite a bit more expensive than the lowest cost ball-bearing and threaded metal rods, but they remove practically all slop and backlash.

- There are basically two types of motors: Servo and steppers. Servo motors are by far the best choice, in that the computer knows where the cutter is at all times. Stepper motors, on the other hand, are moved blindly, and the PC basically hopes that the hardware moved the cutter to the position specified. If the stepper motors get stuck or misses a step, the piece being cut is ruined. The trick is to use stepper motors a lot more powerful than actually necessary. I went that route, as the servo option was too expensive for my budget, and a lot more complicated to set up.

- Control electronics for stepper motors are a lot cheaper than the servo controllers, mostly because stepper motors are being used in practically every computer printer out there, driving the cost all the way down.

- Availability. Before I found a great little shop in the Netherlands, my only choice was e-bay, so I bought both the electronics and the mechanical parts from companies in China.

The quality of my parts are decidedly Chinese, i.e. varying from bad to worse. The linear rails are great though, and I wish I could say the same about the ballscrews. While the ballscrews themselves are really nice, the nylon covers at both end are slightly out of spec, and prevent the ballscrews from moving freely. I hope the nylon will get worn a bit when in use. Also, the ball-bearings I got felt like there was sand in them. I got a handful new ones from a roller-skate shop. The Chinese shaft couplers looks acceptable. One other major problem, besides the nylon on the ballscrews, is the lock-nuts. They need to be machined to the proper size, at some point, before they can be used.

I bought four big-ass stepper motors, and a stepper motor control board and power supply. Everything ready for use by the Mach3 software. I heard a lot of bad things about the Chinese controller boards, but they look pretty decent, and besides, I am an electronics engineer by trade, so I think I can handle those.

All I now need to do is to get the mechanical design done. Since I am only going to cut balsa and plywood, my CNC cutter will be made from MDF board. MDF board is easy to cut and fairly strong. I don’t even have to do such a neat job out of it. When the CNC is up and running, I can use it to cut parts for itself.

08/12/2011

08/12/2011

Leave a reply