To make the fibreglass cowl, I first made a plug with the exact shape of the actual cowl.

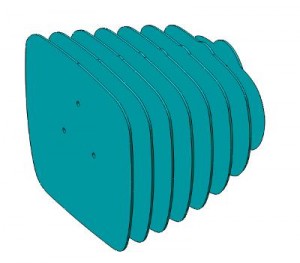

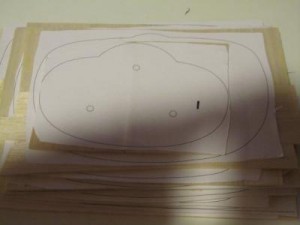

I did this by slicing the CAD model and printing out each slice.

I did this by slicing the CAD model and printing out each slice.

I then cut them out from wood and made a wood/PU-foam sandwich. PU foam is poly-urethane foam. It is similar to the green foam you can get from the florist, except it is much firmer. It can be cut and sanded without worrying about poking a finger through it.

I then cut them out from wood and made a wood/PU-foam sandwich. PU foam is poly-urethane foam. It is similar to the green foam you can get from the florist, except it is much firmer. It can be cut and sanded without worrying about poking a finger through it.

The wood/PU-foam sandwich was then sanded to shape. Any holes and bumps were then filled out and the plug was sanded again. This filling/sanding work continued until it was the right shape and completely smooth. The picture shows the plug after its first sanding/filling cycle.

The plug was then spray painted with an automotive primer. This made the plug real smooth, making any tiny imperfections visible. Filling and sanding was necessary once again.

27/08/2011

27/08/2011

Leave a reply