Percale Fabric

Percale is type of weave most noticeable used for bed-sheets. Percale-woven fabric was initially imported into Europe from India at high cost, but the technology necessary to mass-produce this high-quality fabric was developed in France around the 18th century – the same time balloons were first developed.

Percale is type of weave most noticeable used for bed-sheets. Percale-woven fabric was initially imported into Europe from India at high cost, but the technology necessary to mass-produce this high-quality fabric was developed in France around the 18th century – the same time balloons were first developed.

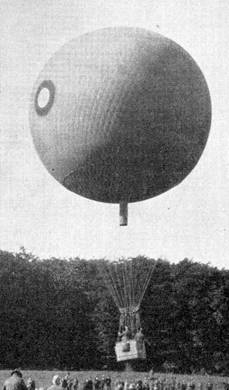

A percale weave has a thread count of about 200 or higher, and is noticeably tighter than the standard type of weave used for bed-sheets. It has medium weight, is firm and smooth with no gloss, and warps and washes very well. Indeed, it is so tight that any pattern has to be printed on. In other words, the ideal fabric for balloon fabrication.

Percale balloons were used until vulcanization of rubber was invented. The first balloons of vulcanized rubber appeared around 1907, made from rubber by the Continental Company.

Percale Balloons

Percale balloons were made from percale and then varnished. The varnish was coated with linseed oil, which, due to contact with oxygen in the air, made the varnish becomes resinous, and over the course of time develop into a hard air-tight mass.

Percale balloons were made from percale and then varnished. The varnish was coated with linseed oil, which, due to contact with oxygen in the air, made the varnish becomes resinous, and over the course of time develop into a hard air-tight mass.

The use of varnished percale, made packing of the balloon difficult. The heat from the sun’s rays during flight, made the varnish soft and sticky. The only way to pack a percale balloon was to take it into the shade or wait until after sunset, and thereby let it cool and re-harden first.

A percale balloon could not be touched until the varnish was completely dry. Because it had a hard surface, it was also easily torn by rocks, or other sharp objects. Furthermore, newly varnished balloons were liable to spontaneous combustion, if packed for more than 20-30 hours. French chalk had to be applied to the exterior of the balloon to prevent this. The chalking process also had to be repeated in wet weather to protect the varnished linen from moisture.

The varnishing process should be repeated after 25-30 ascents.

05/02/2010

05/02/2010

Leave a reply